Ultrasonic Digital Thickness Gauge, Heavy Duty, Model 1 by Cygnus

Cygnus Instruments have designed the Cygnus Heavy Duty ultrasonic thickness gage for use in tough and demanding environments where a rugged construction is essential to accurately gage corrosion measurement and determine metal thickness without having to removing protective coatings.

The Cygnus Heavy Duty is dirt resistant, dust resistant and water resistant. Its shock-proof construction takes into account the unstable environments in which corrosion thickness measurements and structural inspections are performed, resulting in a metal thickness gage that is able to withstand accidental drops, bangs and knocks.

- Heavy duty sealed unit - highly water and dust resistant

- Rugged construction - shock proof

- Stable calibration - linear accuracy - no zero adjustment

- Self verification of the measurements to ensure accuracy

- Various probe options

- Displays sound velocity settings

- Echo strength indicator to aid measurement

- Bright LED display with polarised filter

- Gauge senses probe type and automatically adjusts settings for optimum performance

- Low battery warning

- Metric / Imperial switchable

- Deep-Coat mode for coatings up to 20 mm (3/4") thick.

Options

For optimum performance of the ultrasonic thickness gauge it is essential to utilise the appropriate probe for the specific material being tested. Here below are the probe options available.

Single crystal soft-faced compression

6 mm - 5 MHz

13 mm - 2.25, 3.5 or 5 MHz

19 mm - 2.25 MHz

Kit

Instrument, heavy duty remote 2.25 MHz x 13 mm (1/2") diameter probe, battery pack, spare membranes and ‘O’ rings, steel test block, calibration trim tool, operational manual and carry case.

Applications

Maintenance and safety checks of metal thickness for:

- Metal thickness monitoring on cranes, marine structures and conveying systems

- Corrosion checks on ships’ shell plates, bulkheads and structure

- Metal thickness safety checks on steam and pressurised water systems, transportable gas containers and compressed air systems

- Systematic wall thickness and corrosion monitoring of storage tanks and process vessels

- Quality assurance metal thickness checks

- Maintenance and safety checks on bridges and street lighting columns

- Pipeline wall thickness monitoring.

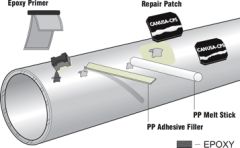

With multiple echo, readings are taken by measuring the time delay between any three consecutive backwall echos. The time of T1 (coating thickness) is ignored. The times of T2 and T3 are equal to the time that it takes to travel through the metal. Only by looking at three echoes can the measurements be automatically verified (where T2 = T3).

Benefits

|

|

| Specifications |

|

Materials |

Sound velocities between 2000 m/s and 7000 m/s |

|

Range |

3 mm to 250 mm with 2.25 MHz probe |

|

Accuracy |

± 0.1 mm or ± 0.05 mm |

|

Resolution |

0.1 mm or 0.05 mm |

|

Probes |

Remote single-crystal, soft-faced compression. |

|

Power Source |

3 x AA alkaline batteries |

|

Display |

Large, clear LED display with polarized filter |

|

Dimension |

240 mm x 75 mm |

|

Weight |

886 g - remote probe |

|

Operating Temperature |

-10°C to +50°C |

|

Warranty |

3 years |