TR Green Tape by Royston

Description

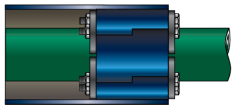

Tapecoat TR Green is 35 mil, cold applied coating designed to provide protection against corrosion and electrolysis on below grade metal substrates. Combined with strong, flexible film backing, Tapecoat TR Green provides a protective coating with cohesive strength and durability that conforms well to irregular shapes.

Tapecoat TR Green has an integrated primer; the primer is in the adhesive. This exclusive formulation allows for faster application as there is no need to apply a separate primer when application temperatures are above 40°F. The Tapecoat TR Green coating system is VOC free when applied without a primer. When used with Tapecoat Omniprime the coating system will meet even the strictest environmental laws.

Recommended Use

The flexible backing makes it a good coating for hand wrapping. Appropriate for coating and reconditioning small to moderate diameter pipe, bends, tees and metal structures, as a single component coating below grade.

Substrate Compatibility

Steel, Stainless Steel, Ductile Iron, other metals, FBE, PE, PP

Surface Preparation

SSPC SP-2 Hand Tool Cleaning, SSPC SP-3 Power Tool Cleaning or SSPC SP-6/NACE No. 3 Commercial Blast Cleaning

Optional Primer

Tapecoat TR Green has an integrated primer to allow for quick, easy and permanent adhesion. When required by the job specification or when application temperatures are below 40°F, a 4 mil WFT of Tapecoat Omniprime may be applied to the pipe surface to ensure the required bond.

Reference

Tapecoat TR Green meet all of the performance criteria listed in the most recent revisions of:

Safety

Refer to Material Safety Data Sheet: MSDS-TC-GRAY

Application

Refer to Application Guidelines: AG-COLD-APPLIED-ELASTOMERIC-TAPE

Technical Data

| Property | US Customary | Metric | Test Method |

| Total Thickness | 35 mils | 0.89 mm | ASTM D1000 |

| Backing Thickness | 7 mils | 0.18 mm | ASTM D1000 |

| Adhesive Thickness | 28 mils | 0.71 mm | ASTM D1000 |

| Cathodic Disbondment, 30 days | <0.4 in² (No Primer) | <10 mm radial (No Primer) |

ASTM G8 |

| Adhesion to Primed Steel | 10 lbf/in | 1.75 N/mm | ASTM D1000 |

| Tensile Strength | 14 lbf/in | 2.45 N/mm | ASTM D1000 |

| Elongation | 800% | 800% | ASTM D1000 |

| Dielectric Strength | Exceeds 12 kV | Exceeds 12 kV | ASTM D149 |

| Holiday Detection Setting | 7400 V | 7400 V | NACE RP0274 |

| Impact Resistance | 20 in lb (double wrap) | 2.3 J (double wrap) | ASTM G14 |

| Water Vapor Transmission Rate | <0.05 g/(24h*100 in²) | <0.003 g/(h*m2) | ASTM E96 Procedure B |

| Water Absorption | <0.2% | <0.2% | ASTM D570 |

| Leachable Chlorides | None | None | |

| Service Temperature Range | -20°F to +125°F | -29°C to +52°C |

Ordering Information

| Roll Size | Rolls Per Case |

| 2” x 50’ | 24 |

| 4” x 50’ | 12 |

| 6” x 50’ | 8 |

Case Packaging: 1.0 SQ (100 ft2) per case

Case Weight: 28 lbs