Link-Seal® Modular Seals, by GPT

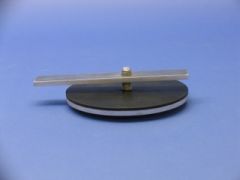

Link-Seal® Modular Seals are considered to be the premier method for permanently sealing pipes of any size passing through walls, floors and ceilings. In fact, any cylindrical object may be quickly, easily and permanently sealed, as they pass through barriers, by the patented Link-Seal® modular seal design.

Ductile iron, concrete, metal as well as plastic pipes may be hydrostatically sealed within walls to hold up to 20 psig (40 feet of head). Electrical or telecommunications cable may be sealed within conduit as they enter vaults or manholes. The annular space between carrier pipes passing through casings may be sealed against the entry of water, soil or backfill material.

With a wide variety of hardware/elastomer combinations, Link-Seal® modular seals are easily configured to achieve the best possible match for service conditions encountered. High temperature seals, fire seals (Factory Mutual Approved) and oil resistant seals may be ordered to meet special or unique service applications.

For the system approach, metal or non-conductive Century-Line® sleeves with water stops may be ordered with Link-Seal® modular seals to ensure correct positioning and a water tight seal of the installation within poured concrete walls.

Standard size Link-Seal® modular seals can be used with Century-Line® Model CS sleeves, Model WS (Steel) sleeves, or core drilled holes. Link-Seal® modular seals are also available for a wide variety of special applications, temperature extremes, exotic chemical combinations and for "out of round" or non-centered applications. Please contact Corrosion Control Products Company for your special application

Features

- Saves time and money...

Link-Seal® modular seals install in up to 75% less time compared to lead-oakum joints, hand fitted flashings, mastics or casing boots.

- Positive hydrostatic seal...

Link-Seal® modular seals are rated at 20 psig (40 feet of head), which exceeds the performance requirements of most applications.

- Long seal life...

Link-Seal® modular seals are designed for use as a permanent seal. Seal elements are specially compounded to resist aging and attack from ozone, sunlight, water and a wide range of chemicals.

- Maximum protection against corrosion...

Standard fasteners with a two-part zinc dichromate and proprietary corrosion inhibiting coating. Corrosion resistant 316 stainless steel available for maximum corrosion protection.

- Certification / Approvals...

Factory Mutual Fire Approvals. Also a wide variety of approvals from various Federal agencies, associations, code groups, laboratories and organizations.

- ISO Quality Assurance...

Link-Seal® modular seals are manufactured in an ISO 9001:2000 certified facility.

- Configure a Link-Seal® modular seal to match your application...

Color coded EPDM, Nitrile, & Silicone elastomers may be used with various hardware options to match performance characteristics with service conditions.

Link-Seal® Modular Seal Sizing Procedure 1 Using Charts for Standard Pipes

Link-Seal® Modular Seal Sizing Procedure 2 for Pipe Sizes not in Charts

Frequently Asked Questions about Link-Seal® Modular Seals

Link-Seal® Modular Seal Options

Model "C or L" Link-Seal® Modular Seals

Model "C or L" Link-Seal® Modular Seals

with Black or Blue EPDM Seal Elements

- Where Used: Suitable for use in water, direct ground burial and atmospheric conditions. Provides electrical isolation where cathodic protection is required.

- Type: Standard.

- Seal Element: EPDM (Black) or EPDM (Blue). Model "L" (Blue) is a low durometer EPDM rubber for thin walled applications.

- Pressure Plates: Reinforced Nylon Polymer.

- Bolts & Nuts: Steel with 2-part Zinc Dichromate & proprietary corrosion inhibiting coating.

- Temperature Range: -40 to +250°F (-40 to +121°C).

Model "S-316" Link-Seal® Modular Seals

with Black or Blue EPDM Seal Elements

- Where Used: For chemical processing & waste water treatment. EPDM rubber is resistant to most inorganic acids and alkalis, some organic chemicals (acetone, alcohol, ketones).

- Type: Stainless.

- Seal Element: EPDM (Black) or EPDM (Blue).

- Pressure Plates: Reinforced Nylon Polymer.

- Bolts & Nuts: 316 Stainless Steel.

- Temperature Range: -40 to +250°F (-40 to +121°C).

Model "O" Link-Seal® Modular Seals

with Green Nitrile Seal Elements

- Where Used: Nitrile rubber is resistant to oils, fuel and many solvents (gasoline, motor oil, kerosene, methane, jet fuel, hydraulic fluid, water, etc.)

- Type: Oil Resistant.

- Seal Element: Nitrile (Green). Note: Not UV resistant.

- Pressure Plates: Reinforced Nylon Polymer.

- Bolts & Nuts: Steel with 2-part Zinc Dichromate & proprietary corrosion inhibiting coating.

- Temperature Range: -40 to +210°F (-40 to +99°C)*

Model "OS-316" Link-Seal® Modular Seals

with Green Nitrile Seal Elements

- Where Used: Combination of oil resistant rubber and stainless steel hardware.

- Type: Oil Resistant.

- Seal Element: Nitrile (Green). Note: Not UV resistant.

- Pressure Plates: Reinforced Nylon.

- Polymer Bolts & Nuts: 316 Stainless Steel.

- Temperature Range: -40 to +210 °F (-40 to +99°C)*

Model "T" Link-Seal® Modular Seals

with Gray Silicone Seal Elements

- Where Used: Silicone rubber is ideal for temperature extremes. "T" model is one-hour Factory Mutual approved.

- Type: High/Low Temperature.

- Seal Element: Silicone (Gray).

- Pressure Plates: Steel Zinc Dichromate.

- Bolts: Steel with 2-part Zinc Dichromate & proprietary corrosion inhibiting coating.

- Temperature Range: -67 to +400°F (-55 to +204°C)*

Model "FD/FS" Link-Seal® Modular Seals

with Gray Silicone Seal Elements

- Where Used: Double seal for added protection.

- Type: Fire Seals.

- Seal Element: Silicone (Gray).

- Pressure Plates: Steel Zinc Dichromate.

- Bolts: Steel with 2-part Zinc Dichromate & proprietary corrosion inhibiting coating.

- Temperature. Range: -67 to +400°F (-55 to +204°C)*

* Note: Sustains a constant temperature of 325°F (163°C). Sustained operation near temperature limits may affect life expectancy.

Link-Seal® Sleeve Options

Century-Line® Model CS Sleeves

ideal for poured wall construction. Made of HDPE thermoplastic, they are lightweight and easy to handle. Molded-in waterstop and reinforcing ribs serve to anchor the sleeve in the wall and resist pour forces. Nailer end caps are provided to make placement in forms simple and accurate. Sleeves are available in 16 diameters, up to 25", and any length. In the event of a field change they can be shortened with ordinary hand tools.

Link-Seal® Modular Seals

Commonly installed in cored wall openings or pre-cast openings such as those formed by use of Cell-Cast® Disks for pipe penetration hole forms. Please see our Cell-Cast Disk pages.

Model WS Steel Sleeves

Made from heavy-wall welded or seamless pipe. A full circle waterstop plate acts as positive water seal and anchor to prevent thrust movement. The collar is continuously welded on both sides. Mo del WS is available in a wide range of diameters and any length. Sleeves are protected by a coating of red primer. Hot dip galvanizing is available on request.

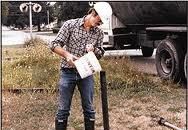

Installation - Link-Seal® Modular Seals

1. Center the pipe, cable or conduit in wall opening or casing. Make sure the pipe will be adequately supported on both ends. Link-Seal® modular seals are not intended to sup-port the weight of the pipe.

2. Loosen rear pressure plate with nut just enough so links move freely. Connect both ends of belt around the pipe.

3. Check to be sure all bolt heads are facing the installer. Extra slack or sag is normal. Do not remove links if extra slack exists. Note: On smaller diameter pipe, links may need to be stretched.

4. Slide belt assembly into annular space. For larger size belts, start inserting Link-Seal modular seal assembly at the 6 O'Clock position and work both sides up toward the 12 O'Clock position in the annular space.

5. Using a hand socket or off-set wrench ONLY, start at 12 o'clock and tighten bolts until rubber begins to "bulge" Do not tighten any bolt more than 4 turns at a time. Continue in a clockwise manner until links have been uniformly compressed. (Approx. 2 or 3 rotations)

6. Make 2 or 3 more passes at 4 turns per bolt max, tightening all bolts clockwise until all sealing elements bulge around all pressure plates. On type 316 stainless steel bolts, hand tighten ONLY without power tool.

7. If the seal doesn't appear to be correct using the instructions provided, call CCP at 310-532-9314

Installation Notes: The Link-Seal® modular seal bolt heads are usually recessed below the wall opening or the edge of casing pipe; therefore a socket or offset wrench must be used.

Hand Tools: Use 5/16" hex or #6 screwdriver for LS-200. 1/2" hex requires 3/8" drive socket wrench. 9/16" and 3/4" hex requires 1/2" drive socket wrench. Tools not provided.

Always Wear Safety Equipment when Installing or Using Link-Seal® modular seals!

|

Link-Seal® Modular Seal - Do's

|

|

Link-Seal® Modular Seal - Don'ts

|

Installation Video

The seller warrants that all goods furnished under this order will be free from defects in material and workmanship and will conform to Pipeline Seal & Insulator, Inc. published specifications.

The limit of PSI's liability for failure of any of our products to meet the foregoing warranty, or for breach of any other warranty, express, implied or statutory, shall be to supply an equivalent amount of product for any materials returned to us within 12 months of shipment and found to be defective by PSI.

Due to the widely varying conditions under which our products are used or installed, PSI offers no warranty as to their merchantability, length of service or suitability for any particular purpose, express or implied, other than described above.

The Purchaser accepts full responsibility for installation of all goods furnished under this order and for any defects or damage suffered as a result of defective installation of such goods. No instructions, advice, or aid relative to installation given by the Seller to the Purchaser shall be construed as a warranty as to the accuracy or utility of such instructions, advice, or aid, but only as an accommodation to the Purchaser and an opinion of the Seller.

The foregoing conditions of sale shall not be modified or affected in any way whatsoever by reason of Seller's receipt or acknowledgement of Buyer's purchase order or any other related instrument of paper containing additional or different conditions and, to the extent there may be any terms or provisions in such a purchase order, etc. which may be in conflict with or modification of the foregoing, such terms and provisions of such purchase order, etc. shall be deemed to have no force or effect.

Typical Seal & Sleeve Specification

1.0 Penetration Seals

Use a modular, mechanical seal, consisting of rubber links shaped to continuously fill the annular space between the pipe and the wall opening. Link-Seal® pressure plates shall be molded of glass reinforced nylon. Hardware shall be mild steel with a 74,000 psi minimum tensile strength and 2-part Zinc Dichromate coating per ASTM B-633 and Organic Coating, tested in accordance with ASTM B-117 to pass a 1,500-hour salt spray test (or 316 Stainless Steel). Coloration shall be throughout elastomer for positive field inspection. Each link shall have permanent identification of the size and manufacturer's name molded into the pressure plate and sealing element. The Contractor will submit to verify the modular seals are domestically manufactured at a plant with a current ISO-9001:2000 registration. Copy of ISO-9001:2000 registrations shall be a submittal item. PSI-Thunderline / Link-Seal® Modular Seal as manufactured by Pipeline Seal & Insulator, Inc. or pre-approved equal.

2.0 Sleeves and Wall Openings

A. For diameters up to 24.81" install molded non-metallic high density polyethylene sleeves (HDPE) with integral hollow, molded water-stop ring four inches larger than the outside diameter of the sleeve itself. End caps and reinforcing ribs, domestically manufactured in an approved ISO-9001:2000 facility. Century-Line® Sleeve as manufactured by Pipeline Seal & Insulator, Inc. or engineered pre-approved equal.

B. For openings from 29.25" to 64.74" in diameter, use a modular hole-forming system consisting of interlocking HDPE plastic discs, domestically manufactured in an ISO-9001:2000 facility. The system shall provide a round hole in conformance with Link Seal® Modular Seal sizing data. Cell-Cast® Hole Forming Discs as manufactured by Pipeline Seal & Insulator, Inc. or engineered pre-approved equal.

Consideration of brands other than mentioned above shall be submitted to the Engineer for evaluation at least 10 days prior to bid due date and shall include evidence of a minimum of 25 years of successful in-service application of the mechanical seal, as well as current ISO-9001:2000 registration.