Cadweld Exothermic Welded C.P. Cable Connections by Erico

Welders, Weld Metal, Tools & Accessories for Cable Attachment

Permanent, Welded Connections

CADWELD connections are made with a semi-permanent graphite mold, which holds the conductors to be welded. Weld metal (a mixture of copper oxide and aluminum) is loaded into the top of the mold. The mold is covered and the weld metal ignited. The exothermic reaction produces molten copper, which produces a permanent, high conductivity connection.

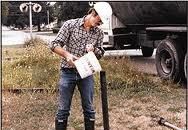

Cathodic Protection Connections

- CADWELD connections are the accepted method of attaching cathodic protection cables to pipes (steel or cast iron), tanks and many other steel structures structures.

- CADWELD connections weld conductors to the object to be protected. Therefore, no galvanic corrosion can occur at the interface. With mechanical connections, surface contacts are present, which can corrode, resulting in an ineffective connection and current path.

- CADWELD connections for cathodic protection use a special alloy to provide minimum heat effect on the steel, especially important on thin wall, high stress pipes.

- CADWELD connections are also used for header cable taps, conductor splices and terminations, and ground rod connections.

A CADWELD Connection...

- Has current carrying capacity equal to that of the conductor.

- Is permanent aand cannot loosen or corrode to cause a high resistance connection.

- Uses lightweight, inexpensive equipment.

- Requires no external source of power or heat.

- Requires no special skills.

- Can be easily checked for quality.

CADWELD Welders and Molds

When making a CADWELD connection, an accurate control of the CADWELD process is accomplished by using a semi-permanent graphite mold. With the mold, control is exercised over the direction and speed of the molten CADWELD weld metal flow and final shape. The graphite used in a CADWELD mold is a high temperature type that lasts for an average of 50 to 100 CADWELD connections under normal usage.

Welder Price Key "CAA" is a solid graphite block with a hold-down handle used for horizontal welding. If a mold only is needed, (without handle), add an "M" to the end of the part number. Example: CAHAA-1G-M

Welder Price Keys CAT, CAP and CAN are split molds and use the Mini E-Z handle. All welders uder these price keys includes the handle or "mold frame".

Refer to the "Welder Price" column on the charts in the "Welder" tab on this page.

When making a CADWELD connection, be sure to use all proper PPE including eye protection, gloves and proper clothing. The CADWELD process is a "hot process" utilzing a molten compound and safety precautions are very important.

EFFECTIVE AUGUST 1, 2018, THE MODEL T320 FLINT IGNITOR IS SOLD SEPARATELY AND WILL NOT BE INCLUDED WITH ANY CADWELD WELDER OR MOLD.

Welder Types

The following Cadweld "welders" are designed to make cable connections to steel pipe or other steel structures. Each welder is designed to work with a specific cable and pipe size in a horizontal or vertical position.

|

Type CAHA

|

| Conductor Size |

Surface | Welder Part No. |

Welder Price |

Weld Metal |

|---|---|---|---|---|

| #14-10 solid, or #8 solid or stranded, or #6 solid |

Flat (4" & larger pipe) 3/4" to 3-1/2" pipe |

CAHAA-1G CAHAA-1GA |

CAA | CA15 |

| 6 Stranded | Flat (4" & larger pipe) 3/4" to 3-1/2" pipe |

CAHAA-1H CAHAA-1HA |

CAA | CA15 |

| 4 Solid | Flat (6" & larger pipe) 3/4" to 3-1/2" pipe 4" to 5" pipe |

CAHAA-1K CAHAA-1KA CAHAA-1KB |

CAA | CA15 |

| 4 Stranded | Flat (6" & larger pipe) 3/4" to 3-1/2" pipe 4" to 5" pipe |

CAHAA-1L CAHAA-1LA CAHAA-1LB |

CAA | CA15 |

| 2 Solid | Flat (10" & larger pipe) 1" to 3-1/2" pipe 4" to 8" pipe |

CAHAA-1T CAHAA-1TA CAHAA-1TB |

CAA | CA25 |

| 2 Stranded | Flat (16" & larger pipe) 1" to 3-1/2" pipe 4" to 8" pipe 10" to 14" pipe |

CAHAA-1V CAHAA-1VA CAHAA-1VB CAHAA-1VC |

CAA | CA32 |

| 1 Stranded | Flat (16" & larger pipe) 1" to 3-1/2" pipe 4" to 8" pipe 10" to 18" pipe |

CAHAA-1Y CAHAA-1YA CAHAA-1YB CAHAA-1YC |

CAA | CA45 |

| 1/0 Stranded | Flat (20" & larger pipe) 2-1/2" to 3-1/2" pipe 4" to 8" pipe 10" to 18" pipe |

CAHAA-2C CAHAA-2CA CAHAA-2CB CAHAA-2CC |

CAA | CA65 |

| 1/0 Stranded | Flat (20" & larger pipe) 2-1/2" to 3-1/2" pipe 4" to 8" pipe 10" to 18" pipe |

CAHAA-2G CAHAA-2GA CAHAA-2GB CAHAA-2GC |

CAA | CA65 |

|

Type CAHC Through conductor to top of horizontal steel pipe or flat surface.

|

| Conductor Size |

Surface | Welder Part No. |

Welder Price |

Weld Metal |

|---|---|---|---|---|

| #14-10 solid, or #8 solid or stranded, or #6 solid |

Flat (12" & larger pipe) 3/4" to 2" pipe 2 1/2" to 5" pipe 6" to 10" pipe |

CAHCA-1G CAHCA-1GA CAHCA-1GB CAHCA-1GC |

CAA | CA25 |

| 6 Stranded | Flat (12" & larger pipe) 3/4" to 2" pipe 2 1/2" to 5" pipe 6" to 10" pipe |

CAHCA-1H CAHCA-1HA CAHCA-1HB CAHCA-1HC |

CAA | CA25 |

| 4 Solid | Flat (12" & larger pipe) 3/4" to 2" pipe 2 1/2" to 5" pipe 6" to 10" pipe |

CAHCA-1K CAHCA-1KA CAHCA-1KB CAHCA-1KC |

CAA | CA25 |

| 4 Stranded | Flat (12" & larger pipe) 3/4" to 2" pipe 2 1/2" to 5" pipe 6" to 10" pipe |

CAHCA-1L CAHCA-1LA CAHCA-1LB CAHCA-1LC |

CAA | CA25 |

| 2 Solid | Flat (14" & larger pipe) 2" to 3-1/2" pipe 4" to 6" pipe 6" to 10" pipe |

CAHCA-1T CAHCA-1TA CAHCA-1TB CAHCA-1TC |

CAA | CA32 |

| 2 Stranded | Flat (18" & larger pipe) 2" to 3-1/2" pipe 4" to 8" pipe 10" to 16" pipe |

CAHCA-1V CAHCA-1VA CAHCA-1VB CAHCA-1VC |

CAA | CA45 |

| 1 Stranded | Flat (18" & larger pipe) 2" to 3-1/2" pipe 4" to 8" pipe 10" to 16" pipe |

CAHCA-1Y CAHCA-1YA CAHCA-1YB CAHCA-1YC |

CAA | CA45 |

| 1/0 Stranded | Flat (30" & larger pipe) 3" to 4" pipe 5" to 6" pipe 8" to 10" pipe 12" to 28" pipe |

CAHCA-2C CAHCA-2CA CAHCA-2CB CAHCA-2CC CAHCA-2CD |

CAA | CA65 |

| 2/0 Stranded | Flat (30" & larger pipe) 3" to 4" pipe 5" to 6" pipe 8" to 10" pipe 12" to 28" pipe |

CAHCA-2G CAHCA-2GA CAHCA-2GB CAHCA-2GC CAHCA-2GD |

CAA | CA65 |

|

Type CAVS Tap conductor to vertical steel

|

| Conductor Size |

Surface | Welder Part No. |

Welder Price |

Weld Metal |

|---|---|---|---|---|

| #14-10 solid, or #8 solid or stranded, or #6 solid |

Flat (12" & larger pipe) 3/4" to 3-1/2" pipe 4" to 10" pipe |

CAVST-1G CAVST-1GA CAVST-1GB |

CAT | CA15 |

| 6 Stranded | Flat (12" & larger pipe) 3/4" to 3-1/2" pipe 4" to 10" pipe |

CAVST-1H CAVST-1HA CAVST-1HB |

CAT | CA15 |

| 4 Solid | Flat (12" & larger pipe) 3/4" to 1-1/2" pipe 2" to 4" pipe 5" to 10" pipe |

CAVST-1K CAVST-1KA CAVST-1KB CAVST-1KC |

CAT | CA25 |

| 4 Stranded | Flat (12" & larger pipe) 3/4" to 1-1/2" pipe 2" to 4" pipe 5" to 10" pipe |

CAVST-1L CAVST-1LA CAVST-1LB CAVST-1LC |

CAT | CA25 |

| 2 Solid | Flat (14" & larger pipe) 1" to 1-1/2" pipe 2" to 4" pipe 5" to 12" pipe |

CAVST-1T CAVST-1TA CAVST-1TB CAVST-1TC |

CAT | CA25 |

| 2 Stranded | Flat (14" & larger pipe) 1" to 1-1/2" pipe 2" to 3" pipe 4" to 6" pipe 8" to 12" pipe |

CAVST-1V CAVST-1VA CAVST-1VB CAVST-1VC CAVST-1VD |

CAT | CA32 |

| 1 Stranded | Flat (18" & larger pipe) 1" to 1-1/2" pipe 3" to 4" pipe 5: to 10" pipe 12" to 16" pipe |

CAVSP-1Y CAVSP-1YA CAVSP-1YB CAVSP-1YC CAVSP-1YD |

CAP | CA45 |

| 1/0 Stranded | Flat (18" & larger pipe) 2-1/2" to 4" pipe 5" to 10" pipe 12" to 16" pipe |

CAVSP-2C CAVSP-2CA CAVSP-2CB CAVSP-2CC |

CAP | CA65 |

| 2/0 Stranded | Flat (18" & larger pipe) 2-1/2" to 4" pipe 5" to 10" pipe 12" to 16" pipe |

CAVSP-2G CAVSP-2GA CAVSP-2GB CAVSP-2GC |

CAP | CA65 |

|

Type CAHB Tap conductor to top of

|

| Conductor Size |

Surface | Welder Part No. |

Welder Price |

Weld Metal |

|---|---|---|---|---|

| #14-10 solid, or #8 solid or stranded, or #6 solid |

Flat (30" & larger pipe) 4" to 24" pipe |

CAHBA-1G CAHBA-1G-P.S. |

CAA | CA25XF-19 |

| 6 Stranded | Flat (30" & larger pipe) 4" to 24" pipe |

CAHBA-1H CAHBA-1H-P.S. |

CAA | CA25XF-19 |

| 4 Solid | Flat (30" & larger pipe) 4" to 24" pipe |

CAHBA-1K CAHBA-1K-P.S. |

CAA | CA45XF-19 |

| 4 Stranded | Flat (30" & larger pipe) 4" to 24" pipe |

CAHBA-1L CAHBA-1L-P.S. |

CAA | CA45XF-19 |

| 2 Solid | Flat (30" & larger pipe) 4" to 24" pipe |

CAHBA-1T CAHBA-1T-P.S. |

CAA | CA45XF-19 |

| 2 Stranded | Flat (30" & larger pipe) 4" to 24" pipe |

CAHBA-1V CAHBA-1V-P.S. |

CAA | CA45XF-19 |

| 1 Stranded | Flat (30" & larger pipe) 4" to 24" pipe |

CAHBA-1Y CAHBA-1Y-P.S. |

CAA | CA65XF-19 |

| Do not use Type CAHB on soil pipe (ASTM A74-82). A test weld should be made on a section of the pipe being used to determine possibility of detrimental metallurgical effects. |

|

Type CAHE Through conductor to top of

|

| Conductor Size |

Surface | Welder Part No. |

Welder Price |

Weld Metal |

|---|---|---|---|---|

| #14-10 solid, or #8 solid or stranded, or #6 solid |

Flat (30" & larger pipe) 4" to 24" pipe |

CAHEA-1G CAHEA-1G-P.S. |

CAA | CA32XF-19 |

| 6 Stranded | Flat (30" & larger pipe) 4" to 24" pipe |

CAHEA-1H CAHEA-1H-P.S. |

CAA | CA32XF-19 |

| 4 Solid | Flat (30" & larger pipe) 4" to 24" pipe |

CAHEA-1K CAHEA-1K-P.S. |

CAA | CA45XF-19 |

| 4 Stranded | Flat (30" & larger pipe) 4" to 24" pipe |

CAHEA-1L CAHEA-1L-P.S. |

CAA | CA45XF-19 |

| 2 Solid | Flat (30" & larger pipe) 4" to 24" pipe |

CAHEA-1T CAHEA-1T-P.S. |

CAA | CA45XF-19 |

| 2 Stranded | Flat (30" & larger pipe) 4" to 24" pipe |

CAHEA-1V CAHEA-1V-P.S. |

CAA | CA45XF-19 |

| 1 Stranded | Flat (30" & larger pipe) 4" to 24" pipe |

CAHEA-1Y CAHEA-1Y-P.S. |

CAA | CA65XF-19 |

| Do not use Type CAHE on soil pipe (ASTM A74-82). A test weld should be made on a section of the pipe being used to determine possibility of detrimental metallurgical effects. |

|

Type CAVH Tap conductor to vertical

|

||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

CADWELD Weld Metal

CADWELD weld metal is a mixture of copper oxide and aluminum, packaged by size in plastic tubes. Each tube contains the starting powder at the bottom of the plastic tube, with the weld metal on top. These containers are packaged, with metal disks, in polyethylene boxes. The welding metal cannot ignite spontaneously. They can be handled and stored without danger and can be shipped with no special packaging or marking.

Two types of CADWELD weld metal are used for cathodic protection connections:

- F-33 alloy is used for all connections of cable to cable and cable to steel or stainless steel pipe. The F-33 weld metal containers have green caps.

- XF-19 alloy is used for all connections to cast iron. XF-19 weld metal containers have orange caps.

| Size | Packed per | |

|---|---|---|

| Box | Std. Pkg. | |

| CA15 | 20 | 100 |

| CA25 | 20 | 100 |

| CA32 | 20 | 100 |

| CA45 | 20 | 100 |

| CA65 | 20 | 100 |

Ductile Iron Connections

Tests by ERICO, Inc. indicate that connections to ductile iron pipe can be made using the CADWELD molds and weld metal designated to be used on steel pipe. However, some reports from the field suggest that all ductile iron is not the same. In some cases, the material for steel will not work. In such cases, the molds and weld material for cast iron do work.

We therefore suggest:

- Whenever possible, make tests on the ductile iron pipe being used to determine if the material for steel can be used.

- Or use the material (XF-19 alloy) for cast iron. It will make satisfactory connections on all ductile iron.

CADWELD Tools and Accessories

|

SHIM STOCK CAB-140-A

|

|

ADAPTER SLEEVES

|

|

| Adapter Sleeve Part Number |

Cable Size | Use in Mold for Conductor Size | ||

| Stranded # | Solid # | Stranded # | Solid # | |

| CAB-133-1H CAB-133-1K CAB-133-1L CAB-112 CAS20F CAS09F CAS05F CAS03F |

12, 14 10 8, 10 6 4 2 1/0 2/0 |

10, 12, 14 8, 10 − − − − − − |

6 − 4 2 2 1/0 3/0 4/0 |

6 4 − − − − − − |

|

|

MOLD CLEANER CAB-136-A

|

|

SHURFIRE CAT-111

|

|

|

|

|

EXTENSION FLINT LIGHTER

|

|

|

CAB-319 VERTICAL PIPE CLAMP

|

|

CAB-320 HORIZONTAL PIPE CLAMP

|

|

|

|

EXTRA CHAINS |

| B323N2 MAGNETIC HOLD-DOWN ASSEMBLY |

|

|

Once attached to the mold handle, the B323N2 securely holds the mold to large flat or slightly curved horizontal steel surfaces during the connection process.

|

B323N2 attached to mold frame on |

| ITEM | CATALOG # |

|---|---|

| Tool Boxes Only | CAT-396 |

| Complete Kit Box and Tools | CAT-343 |

| Complete Kit Box and Tools with Rasp | CAT-343-R |

| RASP (only) | CAT-321 |

| Flint Igniter | CAT-320 |

| Screwdriver | CAT-305 |

| Wire Brush | CAT-336 |

| Crimping Tool | CAT-335 |

| Disk Container | CAT-328 |

| Card Cloth Brush | CAT-313 |

| File and Handle | CAT-329 |

| Mold Sealer | CAT-403 |

| Magnetic hold-down assembly | CAT-B323N2 |

Technical Information

Piping Code

CADWELD CONNECTIONS TO PIPELINES

1. The American Society of Mechanical Engineers* (ASME) publishes codes relating to the design and installation of pressure piping systems:

1.1. ANSI/ASME B31.8- 2000, GAS TRANSMISSION AND DISTRIBUTION PIPING SYSTEMS.

1.2. ANSI/ASME B31.4- 1998, LIQUID TRANSPORTATION SYSTEMS FOR HYDROCARBONS, LIQUID PETROLEUM GAS, ANHYDROUS AMMONIA, AND ALCOHOLS.

2. In both, under Corrosion Control, the standard allows the attachment of electrical leads using exothermic welding but limits the size of the weld metal used to:

2.1. CA15 for steel pipe.

2.2. CA32XF19 for cast, wrought and ductile iron pipe.

3. These restrictions allow for the welding of #4 AWG and smaller wire to steel pipe using Cadweld Cathodic Type CAHA connections and #6 AWG and smaller to cast, wrought, and ductile iron using Type CAHB connections.

When larger sized conductors must be attached to pressure piping systems covered by these codes, several alternative solutions are available:

3.1. Using a Formed Terminal Bond (page 10), a #2 AWG can be welded to cast, wrought and ductile iron with a CA32XF19.

3.2. Using a Cadweld Bonding Strap (page 8), a 1/6” x 1” copper strip (equivalent to slightly smaller than a #1 AWG) can be welded to a cast, wrought and ductile iron pipe with a CA32XF19.

3.3. The “Punched Strap” Bond (page 9) (1/16” x 1-1/4” copper, equivalent to slightly less than a 1/0 AWG) can be welded to steel pipe using a CA15. The 5-hole model is used for “Dresser Type” couplings and the 2-hole model for standard joints.

3.4. The strands of a larger 7 strand conductor can be spread and each strand welded separately (figure 1) as noted in the following table:

* Available from: The American Society of Mechanical Engineers

|

Conductor 7 Strand |

Welder For Each Strand For Steel Pipe |

Weld Metal |

| 4/0 |

CAHAA1H |

CA15 |

| 3/0 to #1 |

CAHAA1G |

CA15 |

| #2 to #4 |

CAHAA1G with sleeve B1331H |

CA15 |

CADWELD CONNECTIONS AND PIPE WALL THICKNESS

The following is a discussion of the minimum pipe size required for safe installation of Cadweld Cathodic Connections considering of the service conditions and without special factory testing. Several things must be considered as outlined below.

For a particular wall thickness:

a. The hoop stress in the pipe will increase as the pipe diameter increases.

b. The heat dissipation will be affected by the thermal characteristics of the material in the pipe.

c. The heat dissipation will be affected by the rate of flow of the material through the pipe while making the weld.

d. The pipe strength will be affected by the temperature of the pipe (material temperature).

e. Any internal coating of the pipe must be checked to find if the temperature of the pipe directly under the weld will adversely affect it.

Based on a minimum wall thickness of 0.109 inches* (2.769 mm) and using a CA15 Weld Metal (the maximum allowed to oil or gas piping systems per ANSI/ASME B31.4 and B31.8), the minimum recommended pipe size and schedule is:

|

Nominal Pipe Size |

Schedule |

Wall Thickness |

|

1/2” |

40 | 0.109 |

|

3/4" |

40 | 0.113 |

|

1 to 2” |

10 | .0109 |

|

2-1/2 to 4” |

10 | 1.120 |

|

5 to 8" |

5 | 0.109 |

|

10" and larger |

5 | >0.109 |

Tests made by operating gas companies indicate no damage to a 4” Grade 52 pipe having a 0.109” wall when making a weld to the pipe at 500 psig using a CA15. Welds made to a steel plate 0.109” thick had a maximum copper penetration depth of less than 0.010”. Other tests on tubes with a 0.125” or 0.150” wall showed a copper penetration of 0.005’ maximum.

DUCTILE IRON

Tests by nVent indicate that connections to DUCTILE IRON pipe can be made using the Cadweld molds and weld metal designated to be used on steel pipe. However, some reports from the field suggest that all ductile iron is not the same. In some cases the material for steel will not work. In such cases, the molds and weld material for cast iron do work.

We therefore, suggest:

1. Whenever possible, make tests on the ductile iron pipe being used to determine if the material for steel can be used.

-OR-

2. Use the material for cast iron. It will make satisfactory connections on all ductile iron.