Protal 7200 Repair Cartridge: Fast Cure Epoxy Repair Coating by Denso

|

|

| 400 mL gun | 50 mL gun |

Description

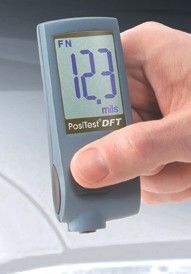

Denso Protal 7200 Repair Cartridges are specially formulated for patching and repairing damaged FBE and other liquid-coated pipelines. The repair cartridges are packaged in 2-component tubes that are applied with a dispensing gun (sold separately). Two convenient sizes (400 mL and 50 mL) are available.

Uses

Repair coating for damaged FBE and other liquid coated pipelines. Also used as coating of Cadweld areas.

Features

- Excellent adhesion (compliments FBE coated pipe)

- Fast cure

- High build (in one coat)

- High abrasion resistance for drilling applications

- Does not shield cathodic protection

Application

Surface shall be roughened approximately 1" around all repair areas using a Carborundum cloth or 60 to 80 grit sandpaper and than remove the remaing dust with a clean, dry cloth, brush or clean compressed air. Material can be applied by injecting material into a small container and mixing until a uniform color is achieved or utilizing the Protal Static Mixing Tip. Material can then be brush applied to specifi ed mil thickness (minimum 20 mils). Cure times are dependent on temperature and will be extended at cooler temperatures.

*Please refer to "Protal 7200 Accelerated Cure Specifi cations for Repairs" to

achieve a 5 minute cure time.

Technical Data

| Properties | Data |

|---|---|

|

Solids Content / Percent Reactive |

100% |

|

Mixed Material (Mixed) @ 77°F (25°C) |

|

|

Mixing Ratio by Volume |

3 Parts Base:1 Part Hardener |

|

Handling Times |

|

|

Recommended Thickness |

25 - 30 mils |

|

Cathodic Disbondment |

|

|

Adhesion to Steel |

3,200 psi |

|

Adhesion to FBE |

2,600 psi |

|

Hardness (ASTM 2240) |

Shore D 85 min. |

|

Gouge Resistance |

3 Passes = 0 Fail @ 50 kg |

|

Application Temperature |

-30°F to 185°F (-34°C to 85°C) |

|

Service Temperature |

-40°F to 185°F (-40°C to 85°C) |

|

Holiday Detection |

125 volts/mils |

| Impact Resistance (ASTM G14-88) | 60.89 in-lbs. |

| Adhesion to Steel/FBE (ASTM D-4541-02) | 3,200 psi |

Handling & Storage

| Properties | Data |

|---|---|

|

Storage |

Minimum 24 months when stored in original containers @ 40°F (4°C) to 105°F (41°C). On job site where temperatures are below 50°F (10°C) product should be kept warm to mix properly (65°F to 85°F optimal). |

|

Cleaning |

Clean equipment with MEK or equivalent solvent cleaner. |

|

Health & Safety |

Apply under well ventilated conditions. Wear suitable protective clothing and glasses. See material safety data sheets. |

|

Packaging |

400 ml and 50 ml dual cartridges. |