Easy Bond Pin Brazing System for Cathodic Protection by BAC

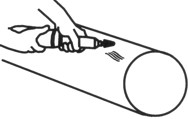

Pin brazing is used to ensure a safe electrical connection to different types of steel structures. The pin brazing method is well suited for joints between pipes, connection to measuring cables, installation of sacrificial anodes, test posts and many other applications. More about the pin brazing process...

Fast and easy connection

Pin brazing of cables gives a safe and durable connection to a pipeline. The automated brazing takes only 1.5 to 2 seconds. Pin brazing is easy to use on site as well as in the workshop.

Pin brazing for cathodic protection

When a cathodic protection system is applied to a pipeline with spigot and sleeve joints, these joints must be electrically bonded. To attach the electric cable connection over the joints, BAC pin brazing can be used. The brazing pins are brazed at both the spigot and sleeve ends of the pipe and the cable attached.

For pipes of ductile or cast-iron, threaded brazing pins are used. Then a prefabricated cable with nuts is fastened. For steel pipes, either threaded brazing pins with nuts are used, or the cable is brazed directly onto the pipe by means of a lug.

In a cathodic protection system, there are often a great number of connections for anode cables, test posts etc. The BAC pin brazing unit contains all the equipment and tools required to make safe cable connections.

The BAC pin brazing system can also use a welding generator as a power source in situations where a great many connections need to be made in one place such as pipe coating yards, lay barges etc.

Operational Notes: Lug Recommendation

-

When using a BAC direct braze pin, it is essential that a BAC cable lug be utilized for attachment of the cable to the structure. Other cable lugs will not work to provide a proper pin braze connection.

-

When using a BAC threaded braze pin, other commercial cable lugs can be utilized for attachment of the cable to the structure.

Typical Brazing Pins

From left to right: Direct, M8, M10

Benefits

-

Speed of Installation

Around one minute per connection. -

Low Temperature

The low melting point of the solder (650°) and short heating time keep thermal effects on the steel to a minimum. -

All-Weather

Wind, rain and cold do not prevent the operator from working safely and effectively. Damp pipes pose no problem. -

Safety

No special equipment or precautions are needed for pin brazing operators. -

Easy to Use

The automated nature of the process means operators can be trained in less than one hour. -

Versatile

The portable nature of the equipment means that connections can be made in almost any location above or below ground, even overhead!

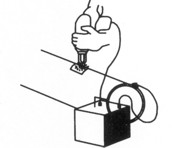

The BAC EASY BOND Pin Brazing Unit is suitable for minor installation and maintenance work. Battery-powered for up to 15 brazes per electrical charge with the smallest type of brazing pin. The unit is portable and easy to transport. The brazing process is controlled by means of the fuse wire on the brazing pin.

The BAC EASY BOND Pin Brazing Unit is suitable for minor installation and maintenance work. Battery-powered for up to 15 brazes per electrical charge with the smallest type of brazing pin. The unit is portable and easy to transport. The brazing process is controlled by means of the fuse wire on the brazing pin.

The BAC PFBG-02 Large Battery Powered Pin Brazing Unit is suitable for larger jobs. It is battery-powered for up to 50 brazes per electrical charge with the smallest type of brazing pin.

EASY BOND PIN Brazing Battery Chargers are available for 110/230 Vac or 12 Vdc. With the latter, batteries can be charged during transportation between workplaces. When alternating between charging and brazing, it is possible to increase effective battery capacity up to 5 times during a working day.

The BAC Pin Brazing Permanent Anode Connection

STINGER permanently connects anode wires with a small diameter to pipes utilizing the unique Silver alloy BAC PIN BRAZING method, without using cable lugs, crimping or old exothermic reactions. More info...

Pin Brazing Equipment & Accessories

| Standard Pin Braze Units | ||

| Equipment Description | Farwest # | BAC # |

|

EasyBond Model MKII, Standard Pin Brazing Kit |

13-26000 | 273-199-5660 |

|

Includes NEW battery unit, Easybond gun, direct pin holder, direct ferrule holder, tool kit, 3 batteries, 110/230 volt charger, ground device, alum. case. |

||

|

EasyBond Model EBRS, Down-hole Reach System Kit |

13-26006 | 273-199-5100 |

|

Includes EasyBond Reach gun & ext. system, trigger device, grinder attachment kit (no grinder), grounding device. Does not include charger, battery box or grinder. |

||

| Common Accessories | ||

| Equipment Description | Farwest # | BAC # |

|

Pin Holder, 8 mm direct pins |

13-26055 | 270-071-5600 |

|

Ferrule Holder, 8 mm direct pins |

13-26051 | 270-074-8150 |

|

Pin Holder, M8 threaded pins |

13-26054 | 273-100-0550 |

|

Ferrule Holder, M8 threaded pins |

13-26052 | 273-100-0560 |

|

Pin Holder, M12 threaded pins |

13-26057 | 273-100-1230 |

|

Ferrule Holder, M10/M12 threaded pins |

13-26053 | 273-100-1240 |

|

Pin Holder, M10 threaded pins |

13-26056 | 273-100-3870 |

| Consumables | ||

| Brazing Pins with Fuse Wires (SOLD IN FULL PACKAGES ONLY) | ||

|

Direct Brazing Pins, 8 mm, 100/pkg |

13-26025 | 278-190-3250 |

|

Threaded Brazing Pins, M8, 50/pkg |

13-26026 | 278-190-0430 |

|

Threaded Brazing Pins, M10, 40/pkg |

13-26029 | 278-190-3450 |

|

Threaded Brazing Pins, M12, 40/pkg |

13-26030 | 278-190-2560 |

| Ceramic Ferrules (SOLD IN FULL PACKAGES ONLY) | ||

|

Ceramic Ferrules, 8mm Direct, 100/pkg (for direct pins only) |

13-26027 | 270-065-7230 |

|

Ceramic Ferrules, 12mm, 50/pkg (for all threaded pins) |

13-26028 | 270-077-3680 |

| Cable Lugs & Sleeves (SOLD IN FULL PACKAGES ONLY) | ||

|

Cable Lug, (#6 - #8AWG), 100/pkg |

13-26041 | 278-100-9890 |

|

Cable Lug, 16 mm sq. cable (#4 AWG), 100/pkg |

13-26046 | 278-100-9000 |

|

Cable Lug, 25mm sq. cable (#2 AWG), 50/pkg |

13-26037 | 270-088-7800 |

|

Cable Lug, 35 mm sq. cable (#1 AWG), 50/pkg |

13-26047 | 270-100-7810 |

|

Cable Lug, 50 mm sq. cable (#1/O and 2/O AWG), 40/pkg |

13-26038 | 270-088-7790 |

|

Cable Lug, #2 AWG, 50/pkg |

13-26043 | 278-100-9850 |

|

Stinger cable "lug", #12 AWG wire 2 hole,100/pkg |

13-26021 | 278-100-8012 |

|

Stinger cable "lug", #10 AWG wire w/ angled hole,100/pkg |

13-26022 | 278-100-8042 |

|

Stinger lug kit assembly, #12 - #20AWG wire, includes Brazing Pin, Ferrule & Stinger lug, 50/pkg |

13-26023 | 278-100-8050 |

|

Stinger lug kit assembly, #10AWG wire, includes Brazing Pin, Ferrule & Stinger lug, 50/pkg |

13-26024 | 278-100-8060 |